CREATIVE, RESEARCH & GREAT POSSIBLITIES

Special Metal Surface Treatment

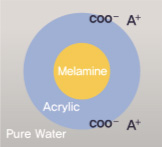

Acrylic Resin Anionic Electrodeposition Coating

Business Introduction

- Acrylic Business Division

This new acrylic resin electrodeposition coating process ensures the original texture of metals and their luster. It forms just a single-coated film, which meets the quality standards of exterior materials including weather resistance and high hardness

Applied to a TV frame, a speaker grill, a stand, etc. Applications: Home appliances, video products, auto interior materials, cell phone cases, interior construction materials, etc.

Applied to a TV frame, a speaker grill, a stand, etc. Applications: Home appliances, video products, auto interior materials, cell phone cases, interior construction materials, etc.

- Anionic Electro Deposition Coating

– This method is to turn electrodeposition paint into anions and then having them deposited on a substrate.

– It is a newly recognized special method for surface finishing

– High hardness and luster are obtained compared to when using other coating methods.

– Only a single-coated film can represent the texture and luster of raw materials.→ Manufacturing costs are reduced.

– It is a newly recognized special method for surface finishing

– High hardness and luster are obtained compared to when using other coating methods.

– Only a single-coated film can represent the texture and luster of raw materials.→ Manufacturing costs are reduced.

About Plants

- Plant #1

– Electrodeposition coating of a TV frame, a sound grill, and a stand

– Material : Steel, SUS, TP, Al, etc.

– Feature: Automatic color change and mass production

Facilities

– Multi-carrier–type anionic electrodeposition systems

– One-line – three-color system

– Tank capacity: 14ton x 3color

- Plant #2 (Headquarters)

– Serving as a preliminary line for Waegwan Branch’s products

– Conducting every kind of test and development task

– Material: Steel, SUS, TP, Al, Mg, etc.

– Feature: Customized production

(can realize colors tailored to customer needs)

Facilities

– In-line (up–down)–type electrodeposition

– Tank capacity: 4.5 T

R & D CENTER

Plastic technology development

Keeping up with global change in parts materials, we develop plastic using the electrodeposition coating system used on plastic substrates.

※ Global trends in change to parts materials

Metal

Heavy and vulnerable to corrosion

Plastic

Lightweight with reinforced carbon composites